Design and production of high-technology ready to use machines and plant.

Listening to your needs since 1998.

Taking you beyond your expectations.

Examples of our products

Maneuvering devices for railway barriers

Electro-hydraulic lifting equipment for mobile barriers for level crossings

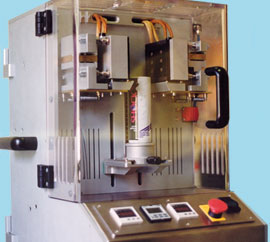

Test systems

Devices for leak testing of industrial speed reducers

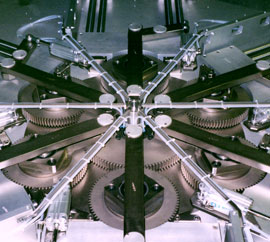

Machines for components of sterile

bags

Rotary machines for inserting tubes and valves into sterile bags for human whole blood and its derivatives

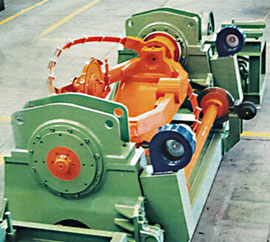

Stranding machines

Machines to manufacture braided steel cables of various sizes

Reams handling systems

Automated plant for picking up and moving reams of paper between handling lines

Industrial grinders

Equipment for trituration of articles in plastic or rubber

Packaging plant

Plant for thermoforming, filling and heat-sealing food products and other substances

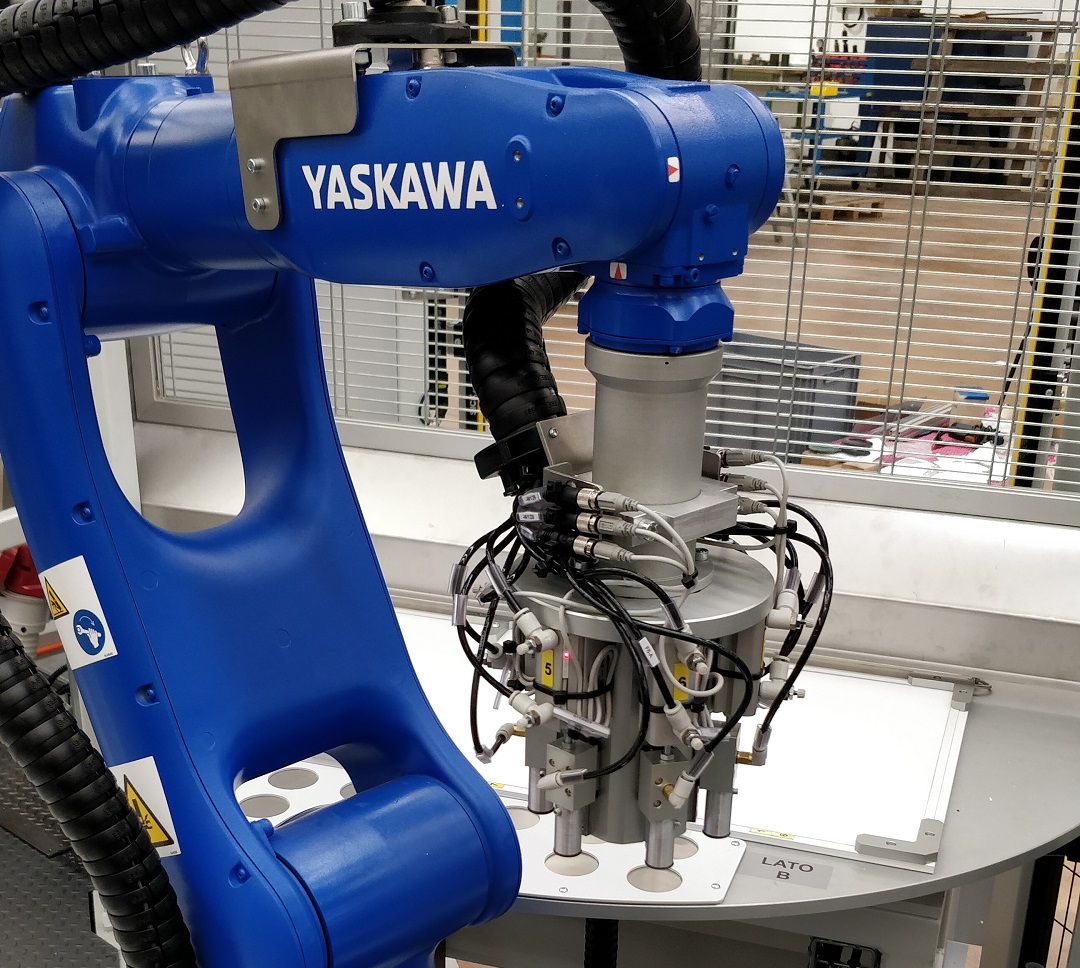

Palletizers

Automated stackers with use of anthropomorphic or Cartesian robots and customised grippers

Positioners for welding process

3-axis CNC systems for a carrying capacity of up to 12,000 kg, combinable with robots

Plant for refrigerator components

Plant for manufacturing refrigerator sanwich coils

Heat-sealing machines

Heat-sealing devices for cosmetic or food product bottles

Packaging machines

Packaging machines for sterile bags of human plasma according to UNI EN 150 9001 and UNI CEI EN 46001

Other Konia products

Cutting system for paper money; biomass drying plant; automotive clutch test benches; Jagenberg's cutting machine retrofitting with torque motors; high output punching machines for aluminium profiles; machine for high precision alignment of sensors for ink position sensing on banknotes; adjustable volumetric metering plant for simultaneous filling of bottles and flacons (up to 60 units); industrial plant and equipment for electrographite production; filter chambers for intake ducts of gas turbines; drawings for review of parts of hydraulic turbines for energy production; apparatus for weight control of boxes on packaging lines with 240 pcs/min speed with automatic tare; test benches for planetary gearboxes; plant for conveyance, conditioning and division of dust samples for size measurement of coal dust by LASER; high speed rotary machines, from 24 to 100 stations, for cast two-component polyurethane; urea transport plant with 450 m conveyor belts, 700 t/h capacity; electro-hydraulic control device for railroad track switches; equipment for self-service payment of toll; machines and modules for producing nappies and sanitary towels; plant for thread dimensional control by LASER of graphite electrodes; modification of casings for ticket emitters with the insertion of a second apparatus; palletising plant for reams of paper money; 21-32 station feeding system for wire of banknotes; CRADLE TYPE stranding machine for three-wire braid ropes or seven-wire steel strands (Ø 16mm); pulling group from Ø 1000 to Ø 1500 mm for stabilization of steel strands (Ø 16mm); expandable spool for coiling harmonic steel strands up to Ø 16mm; worm gear motors for wire-drawing heads from 5" to 20", for harmonic steel rods; 75 t portal-type press with 4 upper mold-holders, 6 lower mold-holders, all transversely positionable by N.C. and complete with electric cylinder-press with roller screw and 4370x3370 screen-holder table positionable by N.C.; security system for overturning curd tanks; washing, ironing and folding machines for industrial laundries; automatic distributors of prepaid cards; PC holder carts.

Our certification

A SELECTION OF OUR CLIENTS

Wherever you find mechanics and automation, you'll find Konia. That is why we have already worked in so many different industrial sectors. Our products are at work in the biomedical, paper, energy production, packaging, measurement systems, infrastructure, food, oil, automotive, household appliances, footwear fields amongst others.

Contact us

Konia s.r.l. - Viale 1 Maggio, 25 - Monte Urano (FM) - 63813 - ITALY

Tel: +39 0734 605066 - E-Mail: info@konia.it

Or, if you prefer, fill out the form below: